Both should open up the Cetus to ABS, ASA, HIPS, PP, PC, nylon, and metal/fiber composite materials.įilament diameter is 1.75 mm with open-source support meaning you can use cartridges from third-parties without any issues although Tiertime does offer its own Cetus-optimized PLA in 700 g spools in a range of colors with low-warp and low-odor properties. Tiertime also offers a heated bed option (up to 100 degrees centigrade) and soon a steel nozzle upgrade. The Cetus supports PLA primarily but is also compatible with PET, PETG, TPU, TPE, PVA, and Wood-filled material.

It’s designed for easy removal of prints while holding them securely in place while the printer is working away and negates the need for painter’s tape, hairspray, glue or your adhesive of choice. The surface is a textured, adhesive layer that sticks to PLA and similar materials. The coating recipe is a well-kept secret on Tiertime’s part. The non-heated print bed consists of 3 mm of aluminum fixed directly onto the Y-axis linear rail with a unique nozzle height error tolerant coating designed to secure the first layer of the print model to the bed. The combination of nozzle diameters and resolutions mean the Cetus is versatile enough to manage both detail-oriented final product printing and quickly-rendered prototypes or draft pieces. The compact single extruder is of the direct drive variety with interchangeable PEEK-made nozzles with diameters of 0.2 mm, 0.4 mm, and 0.6 mm with layer resolutions of 50, 70, 100, 200, 250, 300, and 350 microns. Belted stepper motors assure movement on the axis. The linear rails on each axis ensure quiet, precise functionality with the extruder rail controlling the X-axis, while the print bed runs on the Y-axis, and finally, the extruder rail moves along the Z-axis module. It uses Melted Extrusion Modeling (MEM) print tech with a cantilever design. The build volume is a modest 180mm x 180mm x 180mm that relative to the size and weight (12.1 lbs) of the printer is an amazing ratio. The chassis is constructed with high-quality aluminum extrusions that coupled with the linear rail axis modules, and the low-profile rubber footed mainboard, keep the model upright with a non-chambered, guts exposed, minimalist feel that belies an impressive rigidity. The minimalist, open-ended functionality also extends to modding as the Cetus is ripe for tinkering and add-ons. It’s small and lightweight, but remarkably sturdy while the small footprint and portability mean it is easily transported from home to office or wherever else it might be needed with minimal hassle. Combined they create a small form factor printer without any redundant, frivolous additions nor bells and whistles.

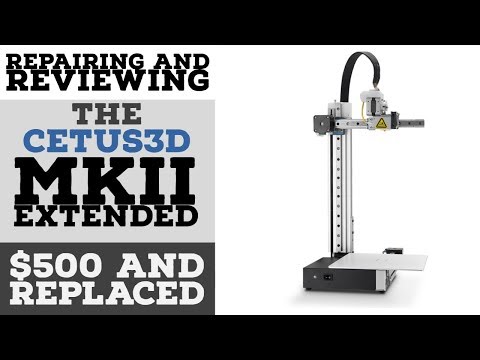

CETUS3D EXTENDED FREE

Is there anyone out there who has solved this problem once and for all, has cetus ever remarked upon it? Please share your strategies if you've overcome this, I would be forever grateful.The Cetus is a minimalist printer whose driving force springs forth from Tiertime’s desire to manufacture a 3D printer free of the complexity that unfortunately defines various models on the market with an emphasis on enjoyment and functionality.Ī quick look at the Cetus reveals a simple, yet intelligent design based on six core modular components: three-axis modules, a main board electronic module, a print bed, and an extruder. I can't seem to trust this printer with large prints, which is especially frustrating as I paid for the extended version - there's just no way I would set a tall print off now. The issue I seem to have with larger prints, is that it clicks while printing the supports - which over the course of a larger print results in failed supports and a failed print. I have found I can reduce the clicking by quite a margin when fine tuning these settings - but I have not been able to completely remove it. To name but a few, I have adjusted things like extruder width, print temps, nozzle size, print height and quality as well as different PLA filaments. However, I do still find myself being overly cautious and printing many tests before trusting it to print larger objects. I have ran tests altering the parameters to mitigate the clicking, and I have had success reducing it. I have had great prints from this machine too, so I know this printer is capable. Since the beginning I've had trouble with the clicking extruder and as a result a few prints have failed. I'm a semi regular user of my Cetus mrk 3 extended 3d printer - with heated bed and self levelling probe( which broke).

0 kommentar(er)

0 kommentar(er)